It is embarrassing that Vietnamese parts suppliers remain unable to make products up to Samsung’s standards, but there are reasons behind this shameful inability, experts said at a forum in Hanoi last week.

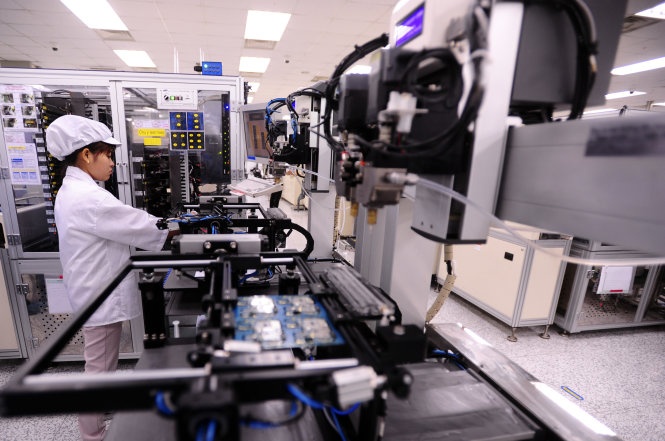

The Saturday event was organized to address the fact that no Vietnamese parts suppliers are able to meet standards set by Samsung to provide goods – even simple ones like screws and bolts – to the South Korean electronics giant’s complex in the northern province of Bac Ninh.

“The case with Samsung is not extraordinary,” Vu Tien Loc, chairman of the Vietnam Chamber of Commerce and Industry (VCCI), which jointly held the event with Dien Dan Doanh Nghiep (Business Forum) newspaper, said.

“Previously, Canon and Sony could only partner with local firms in making packaging for their products.”

Loc said this has ‘wounded’ the pride of Vietnamese firms, thus prompting the need to carefully discuss the reasons behind the issue and work out solutions to “enable [them] to reach world-class levels.”

Earlier last month, Minister of Industry and Trade Vu Huy Hoang asserted that Vietnamese firms are capable of producing screws and bolts with assured quality, but “whether these parts can enter the production chain of Samsung is a different story.”

“It’s obvious that if Vietnamese firms cannot ensure a competitive production cost, they can hardly enter any global value or distribution chains [like Samsung],” Hoang said during a televised Q&A show on national TV channel VTV3.

But Hoang’s statement has been deemed as irrelevant, and the attendees at the Hanoi forum know exactly why local parts suppliers cannot be chosen by Samsung.

The VCCI chairman pointed to what he said is an “unfair business environment” in Vietnam.

“Many businesses can still remain competitive without investing in technology upgrades thanks to their ‘relationship’ [with regulatory bodies],” Loc elaborated.

Tran Viet Thanh, deputy minister of science and technology, admitted that most Vietnamese suppliers are employing technology that is two to three generations behind their global peers.

Only 12 percent of the businesses have advanced technology, most of which are foreign-invested firms, and the remaining 88 percent are utilizing outdated technology, Thanh said.

“The money Vietnamese businesses earmark for upgrading their technology only accounts for less than 0.5 percent of their revenue, while the figure in South Korea is 10 percent, or a 20-fold disparity,” he said.

The local firms have imported new equipment and machinery, but mostly from China, he added.

Economic expert Nguyen Minh Phong said the government should have mechanisms, policies, and support in place for businesses to be able to produce world-class products.

But Nguyen Anh Tuan, chairman of Hanoi-based Thang Long Tech Co, believed businesses should “save themselves instead of waiting for government support.”

“Instead of working independently, businesses should link with each other to be able to join the global value chain,” he said.

Like us on Facebook or follow us on Twitter to get the latest news about Vietnam!