A group of university students in Ho Chi Minh City have come up with an initiative to turn banana trunks that would otherwise go to waste into eco-friendly paper bags and organic fertilizers.

The four-member team, all majoring in biotechnology at Van Lang University, are proud they are part of the initiative, launched to wondrously transform banana trunks into objects both environmentally sustainable and eye-catching.

A thing that matters to the students is how their environment-friendly ideas have supported local farmers through upcycling the trunks after each banana harvest.

Use of banana trunks is traditionally limited to animal feed as they are cut up into small pieces to feed poultry in rural areas.

After one year of development, the biodegradable, low-cost product is expected to make a splash for its simplicity, environment-friendliness, and safety.

It typically takes nearly one week to make a paper bag manually.

With the pseudostem – the part of the banana plant that looks like a trunk – hand-picked and leaf sheaths split, the group members move on to batter and dry the sheaths before cutting them into small pieces and soaking them in a sodium hydroxide solution.

Next come boiling, grinding the mixture into a smooth paste, and pouring it into molds before the bags can be crafted.

The items come in different sizes, with prices varying from VND6,000 (US$0.3) to VND21,000 ($0.9) apiece.

Bearing in mind that nothing would go to waste, the students ingeniously transform the inside of the trunk into organic manure, priced at VND2,500 ($0.1) per kilogram.

According to Huynh Anh Bao, the group leader, while all the production phases are performed manually for now, their next steps are to make technical advancement so that the items will soon make their way onto market shelves at an affordable price.

He added his team will also try their hands at packaging from banana leaves as an eco-friendly alternative soon.

|

|

| The banana pseudostem – the part of the banana plant that looks like a trunk – is cubed for easier processing. Photo: Ngoc Phuong / Tuoi Tre |

|

|

| After being brewed, the banana cubes are boiled. Photo: Ngoc Phuong / Tuoi Tre |

|

|

| The mixture is rinsed carefully and only the residue will be used. Photo: Ngoc Phuong / Tuoi Tre |

|

|

| Tuyet Ngan, one of the research team members, blends the mixture into a fine paste. Photo: Ngoc Phuong / Tuoi Tre |

|

|

| It takes up to 600 milliliters of banana paste to produce pulp before it is crafted into bags. Photo: Ngoc Phuong / Tuoi Tre |

|

|

| Lan Anh (right) notes that as banana is rich in cellulose content, paper bags made from banana trunks will be a lot suppler and tougher than their traditional counterparts. Photo: Ngoc Phuong / Tuoi Tre |

|

|

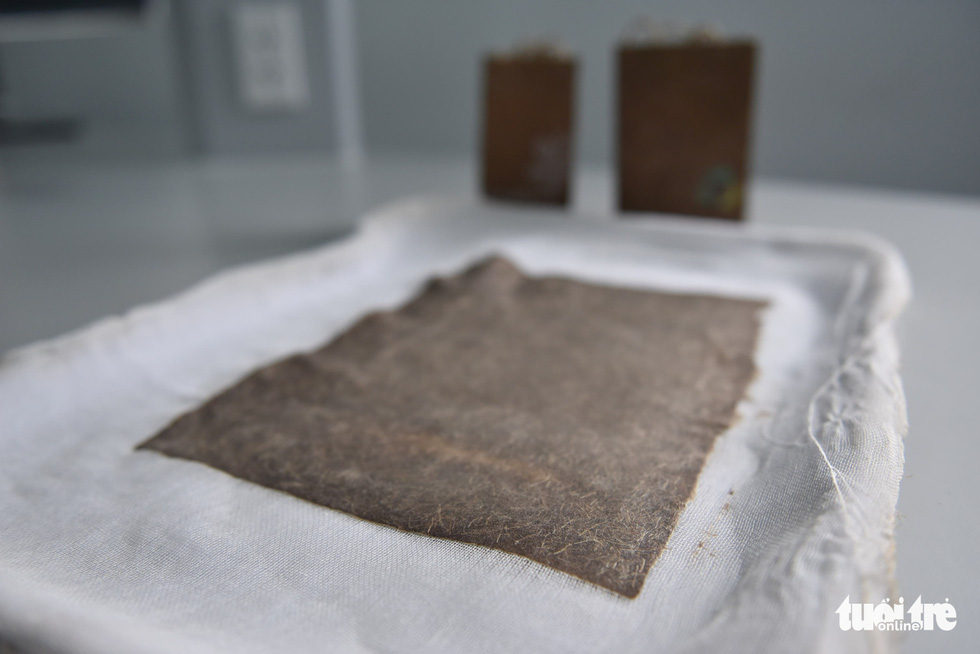

| The banana remains are the first to be made into paper. Photo: Ngoc Phuong / Tuoi Tre |

|

|

| It takes three days for the remains to dry out on their own and one week for an eco-friendly bag to take shape. Photo: Ngoc Phuong / Tuoi Tre |

|

|

| The final products are the biodegradable, low-priced paper bags. Photo: Ngoc Phuong / Tuoi Tre |

|

|

| Organic manure, priced at VND2,500 ($0.1) per kilogram, is made from the banana core, leaves, and barks. Photo: Ngoc Phuong/ Tuoi Tre |

|

|

| Prices of the biodegradable paper bags vary from VND6,000 ($0.3) to VND21,000 ($0.9) apiece depending on their size. Photo: Ngoc Phuong / Tuoi Tre |

Like us on Facebook or follow us on Twitter to get the latest news about Vietnam!