As promulgated in Decree No. 15 issued by the Vietnamese government in 2018, which details the implementation of the Food Safety Law, starting from July 1, 2019, all producers of functional foods and foods for health protection must meet Good Manufacturing Practice (GMP) in order to launch their products.

So, what is GMP? And which equipment helps food and pharmaceutical warehouses to be qualified for GMP?

GMP and things to know

GMP is a system for ensuring safe and hygienic conditions for production. It is designed to consist of general principles, regulations, guidelines for basic content of production conditions; and applied to establishments or facilities engaged in producing, processing, packing foods, pharmaceuticals, medical equipment, cosmetics, and others in order to ensure that these products meet the quality and safety standards.

GMP is a fundamental part of the food safety management system, which is a prerequisite for the development of HACCP systems and ISO 22000 food safety management standards.

GMP links with all aspects of the manufacturing process and quality control of a product: designing and installing warehouse, input materials, processing tools, equipment and machines, specifications of the processing, packaging, and the working process, making sure they comply with regulations on food hygiene and safety for all employees to bring a logical and scientific quality management method and working system, raising high productivity and qualified products.

Areas which GMPs are applied to

Currently, GMPs are applied in the fields of manufacturing, processing and trading of products with high requirements on hygienic conditions such as pharmaceutical, food, cosmetics, and medical equipment.

GMP requirements include equipment and facilities, production materials, production process, packing system, product storage and distribution, and sanitation and waste treatment.

Depending on features of each field and industry, manufacturers are required to meet specific standards for input materials, production equipment, production processes, packaging, and working processes of workers.

Additionally, manufacturers also need to pay their special attention to general standards of the structure, design and installation of warehouses and associated equipment, product storage systems, sanitation and waste treatment so that warehouses are well ventilated, safe and hygienic, ensuring product quality and employee health.

Following are three must-have devices for a GMP-certified establishment or warehouse:

Dock Shelter/ Dock Seal Rite Hite

|

| Dock Shelter GABMASTER Rite Hite |

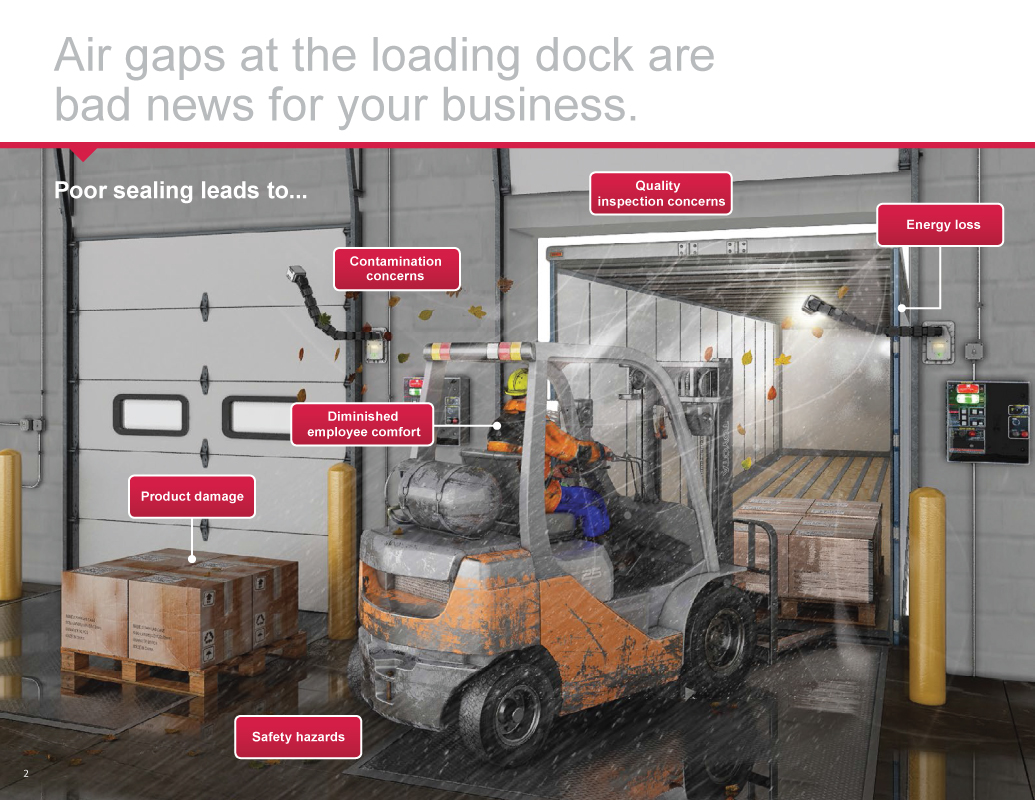

Dock Shelter, Dock Seal Rite Hite is a canvas system fully covering the contacting area between the truck and the loading/unloading door.

It not only provides the truck with safe and effective access to the area but also helps to cover up any gaps in three sides of the door.

The key feature that really helps Dock Shelter and Dock Seal to become the first choice of managers is that it prevents adverse environmental conditions such as wind, dust, insects, and others from entering the warehouse, without any gap or light at the position reached by Dock Shelter / Dock Seal Rite Hite.

It also ensures the warehouse in good conditions of hygiene and safety, and product quality to meet the above GMP standards.

|

| Gaps at the loading/unloading door area constitute many threats to manufacturers. |

For a normal warehouse, it does not have a really major impact. But for food, pharmaceutical, and medical warehouses that require an absolutely clean and stable environment, it is extremely important.

Moreover, Dock Shelter and Dock Seal Rite Hite also help prevent cold air leakage when there is a temperature difference between a cold warehouse and the outside environment.

If the loading/unloading is taken place at a high intensity, the warehouse shall be kept at a standard temperature to ensure the freshness of food.

High Speed Door FasTrax Rite Hite

Each warehouse is divided into separate areas, including raw material area, production area, finished product area, laboratory, and inventory area.

Depending on the characteristics of each area, the conditions and temperatures must be set up to meet separate hygiene standards.

Workers moving from one area to another to work shall easily cause instability and change in environmental conditions in each area.

In particular, if there is any change in areas that require extremely high cleanliness, or cold storage areas, it will affect the hygiene and product quality.

|

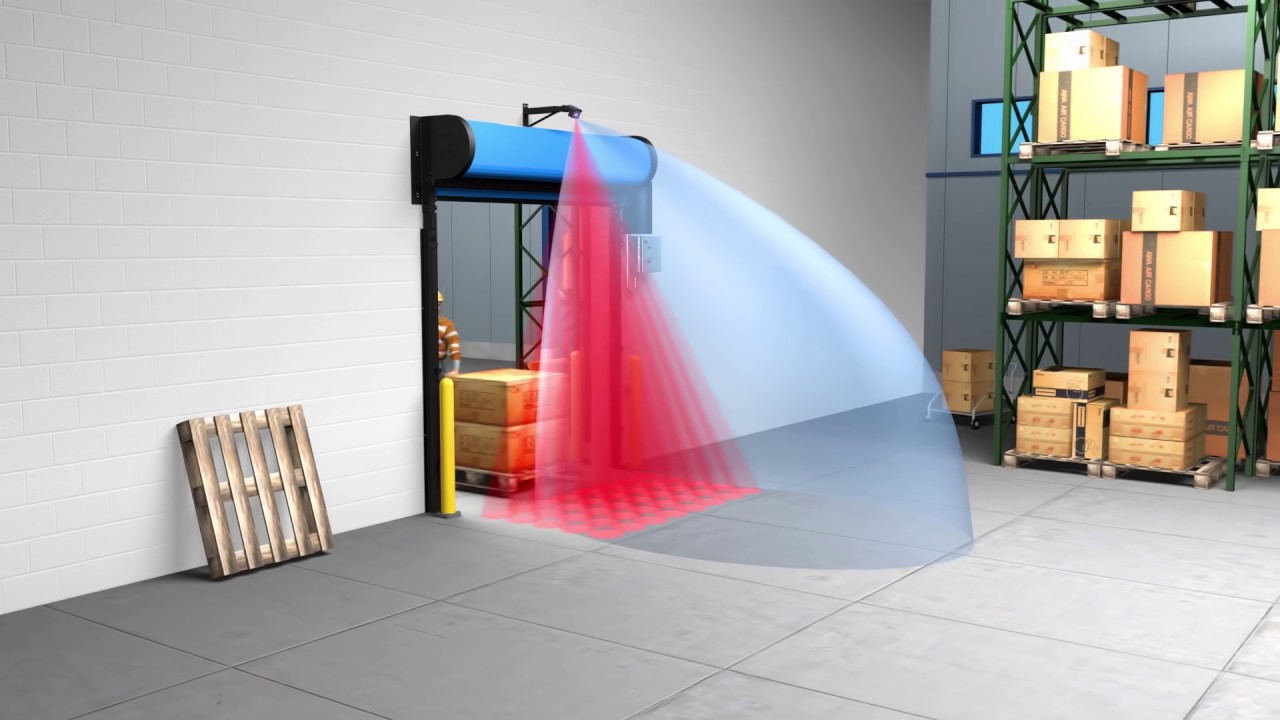

| A sensor can identify the motion of people/vehicles near the doorway. |

High Speed Door FasTrax Rite Hite meets the above requirements because it has a super-fast opening and closing speed of 100''/s (2.5m/s) to help control the environment in each area.

The motion sensor placed at the top of the door helps the FasTrax Rite Hite identify people and vehicles moving near to the door, automatically opens and closes at the highest speed.

High Speed Door FasTrax Rite Hite is made of the softest material in the industry, without hidden metal or plastic and buried wires.

Being made of 100% fabric makes the door softer, ensures the safety of products, operators and devices.

Pressed aluminum or stainless steel frame keeps the door cleaner and ideal for installation in a narrow space. In particular, users can easily disassemble and clean the door when needed.

High Volume Low Speed Fan Rite Hite

High humidity in the air, rainy weather and operation process in wet conditions result in the warehouse being in a humid condition all the time.

Products, machines, walls and floors with water sitting on them will cause adverse impacts on product quality, working conditions and employee health, and facilitate insects to destroy the development of products.

|

| HVLS Fan Rite Hite with coverage of 22,000 square meters |

Thanks to HVLS Fan Rite Hite with a coverage of up to 22,000 square meters, airflow throughout the area helps maintain a stable temperature in the warehouse, creating cool and dry conditions for all facilities.

Instead of cooling functions like those of other conventional fans, HVLS Fan Rite Hite helps to condition the air, bringing a comfortable working environment to all employees.

HVLS Fan Rite Hite is a smart choice for many businesses with large spaces.

Japan — a leader in technology, creativity and always putting users’ experience as the top priority, is the nation with the bestselling HVLS Fan Rite Hite in the world, accompanying many businesses.

RotoAccess VN Co., LTD — the exclusive distributor of Rite Hite warehouse equipment in Vietnam

Website: www.rotoaccess.com.vn

Hotline: (+84) 838 11 11 33

Email: Sales.vn@rotoaccess.com.vn