These days paintings crafted from traditional lacquer are increasingly harder to come by due to local artists’ preference for industrial lacquer and the lack of strategies to properly develop the country’s resin industry, according to local experts.

First adopted in Vietnam since around 1930, lacquer artworks in the early days were the combination of traditional lacquer resin and the artists’ time-consuming process of polishing the finish several times with water to create satisfactory colored layers.

Traditional lacquer is extracted from lacquer-yielding trees scientifically termed “Rhus succedanea,” which grow profusely in northern Vietnam’s Phu Tho Province.

Lacquer is typically used in paintings and applied onto other handicraft items, such as statues, decorative wares and horizontal boards engraved with Chinese characters, as a tasteful, highly durable cover.

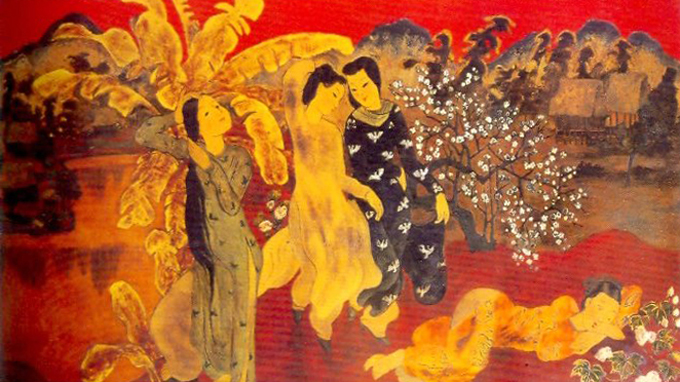

During the 1940s and 1950s, outstanding traditional lacquer works by such renowned artists as Nguyen Gia Tri -Vietnam’s father of lacquer and one of the country’s prominent artists, Nguyen Tu Nghiem and Tran Van Can catapulted the material to a new height.

To Ngoc Van, another eminent Vietnamese artist, also predicted an even brighter future for the country’s traditional lacquer artworks.

However, as Jean François Hubert, a French senior expert of leading auction houses Christie's and Sotheby's, remarked last year, Vietnam’s traditional lacquer art has seen a decline in recent years.

Except a group of 38 members in Hanoi and some dozens of others in Hue City of central Vietnam’s Thua Thien- Hue Province and Ho Chi Minh City, most artists now favor industrial lacquer from Japan or silk printing ink as the new materials are considerably more convenient, and time and energy saving.

In addition, the lacquer-yielding forests in Vietnam have been shrinking in area, resulting in poorer, lower-quality supplies of lacquer resin.

In recent years, traditional craft villages such as Ha Thai, Chuyen My and Chuon in Hanoi, Dinh Bang and Cat Dang in northern Vietnam’s Bac Ninh and Nam Dinh provinces have also switched to industrial lacquer and adopted more machine-run production phases.

Local experts also put the declining use of traditional lacquer down to the lack of a systematic, comprehensive growth of the local lacquer industry.

They also pointed to the inconsistencies between phases such as planning, lacquer resin production, crafting and exhibiting the lacquer artworks.

Research on the lacquer-yielding trees also remains rudimentary and outdated, with current production based mostly on the materials borrowed from French experts in the early 20th century.

Like us on Facebook or follow us on Twitter to get the latest news about Vietnam!