NEW YORK -- Big pharmaceutical companies that make personalized blood cancer treatments are working to cut the manufacturing turnaround time by as much as half in coming years, as they try to deliver them sooner in a patient's disease course.

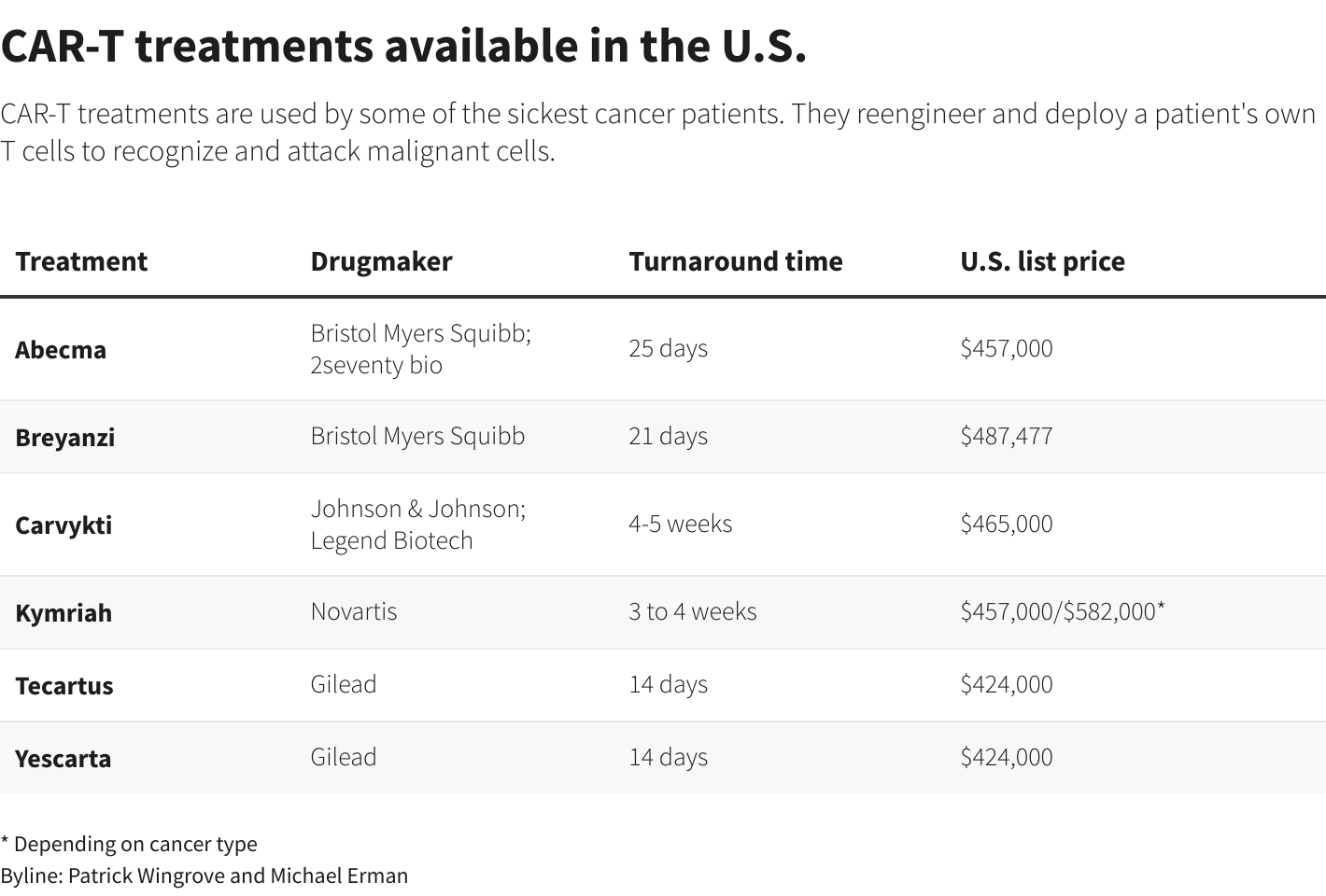

These treatments known as CAR-T therapies are used for the sickest patients for whom standard treatments have failed. They involve removing a patient's T cells - a key component of the immune system - after which they are re-engineered to recognize and attack malignant cells once they are re-infused.

Gilead Sciences, Novartis, Johnson & Johnson, and Bristol Myers Squibb have made billions from their treatments, which can extend lives by months or years for patients with aggressive advanced cancers.

Trimming days or weeks from the time it currently takes between removing and reintroducing the cells to a patient could open the treatment to those who otherwise would become too sick during the process, according to three doctors, the companies and analysts.

Prices for the one-time treatment range from $400,000 to nearly $600,000, and analysts estimate they currently have profit margins of about 50 percent, so expanding the patient population is not insignificant.

![[2/5]Employees move media used in the manufacturing process at Gilead unit Kite's manufacturing facility in Frederick Maryland, U.S., March 14, 2024. Photo: Reuters](https://static.tuoitrenews.vn/ttnew/r/2024/07/25/https---cloudfront-us-east-2-images-arcpublishing-com-reuters-w7gwjr4wgvni5nltcqjgfgqjxq-1721880027.jpg) |

| Employees move media used in the manufacturing process at Gilead unit Kite's manufacturing facility in Frederick Maryland, U.S., March 14, 2024. Photo: Reuters |

Oppenheimer & Co analyst Hartaj Singh said only around 1 in 5 eligible patients receive CAR-T treatments.

"It's complex manufacturing using the patient's own cells, but because some of the responses reported are just so long and durable, physicians will go to it," Singh said. "It's the biggest gun out there."

Time to treatment, which was as long as 37 days when the first CAR-T therapy was launched in 2017 by Novartis, are now down to 14 days at Gilead. Improvements in automation and regulatory adjustments could help companies further trim that time.

Singh said physicians suggested to him that a one-week turnaround could expand these treatments to 2 or 3 out of 5 eligible patients.

|

|

| Employees train to be cell therapy specialists at Gilead unit Kite's manufacturing facility in Frederick Maryland, U.S., March 14, 2024. Photo: Reuters |

Improvements in manufacturing time could be a competitive edge when therapies are approved for the same cancer or population and directly compete, and could give companies a leg up on more quickly available treatments such as antibodies or antibody drug conjugates, he added.

To make the treatments, a patient's T cells are isolated, frozen and shipped to manufacturers. Once received, the cells are purified, modified and expanded to large enough numbers to treat the patient. They then go through quality control processes before being re-frozen and shipped back for infusion.

Gilead is testing new technology it hopes can cut two days from the manufacturing process by using healthier and more potent younger cells.

The company is also looking to fully automate some parts of manufacturing that are now semi-automated and gain regulatory approval to shorten the quality control time.

Novartis is aiming for 10 days or less in the U.S. for its next generation of treatments through its rapid manufacturing platform T-Charge. Its treatment, Kymriah, currently takes 3 to 4 weeks with a target of 22 days.

Novartis said the T-Charge system would shorten the manufacturing time because it allows for the engineered cells to multiply within the patient, reducing the need for extended cell expansion before infusion.

|

|

| A transportation container used to keep the product cold while it's in transit is pictured at Gilead unit Kite's manufacturing facility during a tour in Frederick Maryland, U.S., March 14, 2024. Photo: Reuters |

'Every day matters'

Dr. Chijioke Nze of MD Anderson Cancer Center in Houston said a manufacturing time of a week would be ideal.

Frailer patients can develop kidney or liver dysfunction while they wait for their therapy to be manufactured or may become too weak to be able to successfully undergo treatment, Nze said. He has prescribed Gilead's Yescarta and Tecartus as well as Bristol Myers' Breyanzi.

"The patient population that needs CAR-T cell therapies generally have the more aggressive of an already aggressive disease," he said.

Analysts and drugmakers say using CAR-T drugs earlier before doctors first prescribe multiple other treatments that fail to help patients would also expand use. J&J’s Carvykti, for example, was approved in April for patients who did not benefit from just one other treatment for multiple myeloma.

Some CAR-T approvals require patients to receive three or four other treatments to fail before using the therapy.

Increasing the number of hospitals and health centers offering the treatments also will make it feasible for more patients, they said.

Since 2017, over 42,000 people globally have received CAR-T treatments. Six are approved in the U.S. for the treatment of blood cancers, including lymphomas and some forms of leukemia.

|

|

Lynelle Hoch, who leads Bristol Myers Squibb's cell therapy business, said its current focus is on increasing manufacturing capacity. Still, it said its time to produce the treatments is trending lower and will be helped by its collaboration with Cellares, a development and manufacturing organization with a fully automated cell therapy production platform.

J&J in a statement said it doubled its CAR-T manufacturing capacity last year and is striving to double it again in 2024. It said it is working to further reduce treatment times.

Cindy Perettie, an executive at Gilead's Kite cell therapy unit, said in an interview that lymphoma patients who have already tried two treatments generally only have months to survive and need to get treated as quickly as possible.

"Every day matters for these patients.”

|

|

| Cindy Perettie, Executive Vice President of Kite, poses for a portrait at Gilead unit Kite's manufacturing facility in Frederick Maryland, U.S., March 14, 2024. Photo: Reuters |

![[3/5]Employees train to be cell therapy specialists at Gilead unit Kite's manufacturing facility in Frederick Maryland, U.S., March 14, 2024. Photo: Reuters](https://static.tuoitrenews.vn/ttnew/r/2024/07/25/https---cloudfront-us-east-2-images-arcpublishing-com-reuters-6dlgsxiwt5m7zjoqg5t7ncuvsq-1721880027.jpg)

![[4/5]FILE PHOTO:A transportation container used to keep the product cold while it's in transit is pictured at Gilead unit Kite's manufacturing facility during a tour in Frederick Maryland, U.S., March 14, 2024. Photo: Reuters](https://static.tuoitrenews.vn/ttnew/r/2024/07/25/https---cloudfront-us-east-2-images-arcpublishing-com-reuters-3jxummmvvfjfripswb32x3q7pe-1721880027.jpg)

![[5/5]Cindy Perettie, Executive Vice President of Kite, poses for a portrait at Gilead unit Kite's manufacturing facility in Frederick Maryland, U.S., March 14, 2024. Photo: Reuters](https://static.tuoitrenews.vn/ttnew/r/2024/07/25/https---cloudfront-us-east-2-images-arcpublishing-com-reuters-axwgt6vhkjomlnhertfjgyozae-1721880027.jpg)